The global population is becoming increasingly more aware of the effect of greenhouse gases, and moreover the sources of these gases. In an overall stance to become more environmentally conscience through responsible consumption, consumers are looking at producers to improve what is available to them.

As beauty products are mostly daily use, there is potential to either save or waste a lot of resources. Beauty and Personal Care brands have an important role to play as the act of reducing waste is not for packaging alone, but is a greater movement of Upcycling!

From Waste to Worthy

When food is wasted, it also wastes the resources – such as the land, water, energy and labor – that go into growing, storing, processing, distributing, and preparing that food. Consider this: products we use in North America that are derived from feedstocks leave 40% of the plant inedible, such as skins, peels, leaves, rinds, seeds, pits and cores of may fruits. This creates an immense opportunity to upcycle resources we have already used the energy to obtain.

So what exactly is upcycling?

Simply put, upcycling is the creation of new products from the waste, and by-product remaining after the production of an entirely separate product. It is repurposing a material that was previously thought to be of no use.

Waste = scraps, leftovers (i.e. peels, pits, leaves, stems)

By-product = secondary product obtained by manufacturing of the main product:( i.e. oils, alcohols, starches, pulp)

In consumer goods manufacturing this entails moving from a linear to a circular economy. This means analyzing the starting sources of ingredient materials across industries and better utilized outputs. Let us illustrate, literally!

Wow, That is Hard to Argue!

Tell me about it! What else you should know is that the younger generations are drivers for more sustainable practices. In fact, 57% said they want their purchases to be environmentally sustainable. When we look at upcycling they are now the biggest proponents for second-hand shopping, and when asked by Mintel about products made from food waste 58% of 16-24 year olds in the US said they would buy vs. 44% of the rest of the population. The Upcycled Food Association says this is because 95% of us want to do our part to reduce food waste, Are your part of that large number?

By neglecting to look at our sources in entirety we are using two oranges in this case for two different parts of the fruit that are incorporated into two different end products, taking those two parts from the same fruit still allows for two different end products, with less resources to create them. Changing our process to circular from linear decreases the resources used by over half or more.

Here is Where You Start:

BioActives – Responsibly Active Program

From Trash to Treasure; What’s the Catch?

Less reposible partners. As an example, oil extraction has been under scrutiny because of the recent and extreme rise in wellness practices and holistic healing. The resources and waste created through those traditional processes is something that can be avoided with the Oléo-éco-extraction process. Through this technology, ingredients of high purity and yield are produced without the use of organic solvents and other pollutants — in a way that is ecologically sustainable. The following Oleoactif ingredients are made out of the seeds, stems, leaves, roots or flowers of various plants and this patented process:

Through revalorizing by-products, considered as wastes in other industrial activities (such as the food industry), and enhancing all plants constituents out of products such as wheat, maize, potato and pea to generate less than 0.5% of waste from those feedstocks, we can offer natural ingredients with a highly sustainable approach that is focused on the future!

OLIVE EXFOLIATOR 200 is manufactured from olive kernel, coming from olive oil manufacturers.

MICROZEST 50 COCOA is manufactured from cocoa shells, coming from cocoa beans extraction.

GREEN MICROZEST 50 CHARCOAL is manufactured from coconut shells.

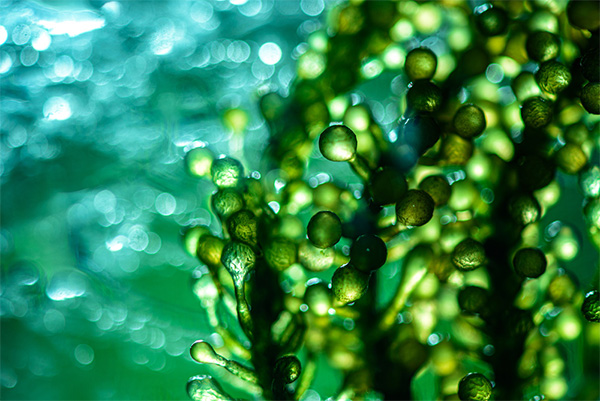

FUCOREVERSE is manufactured from an alginate extraction by-product.

MARINE SERUM & SEATRACE are the residual water from saline marshes.

BIOMICROZEST 25 ARGAN is a by-product from argan oil manufacturers.

LYCOMEGA is a mix of tomato seeds oil and cranberry seeds oils.

MICROZEST 25 LEMON & MICROZEST 25 ORANGE are manufactured from citrus peels, coming from fruit juice industries.

SAPONIN+ is an extract of tea seeds cake, coming from tea seeds oil extraction.

C+ERAMIDE is manufactured from a starch extraction by-product

CLEANSCRUB 300 is manufactured from corn cob

Formulas to Meet Your Upcycled Levels

- Cleaning Paste with 80% upcycled ingredients!

- Dry Exfoliating Cleanser with 100% upcycled ingredients!

- Hair Mask 100% natural; 55.3% vegetal sources,; 20.3% upcycled

- Styling Hair Lotion with 95% upcycled ingredients!

- Nutrition Milk to Soothe Skin with 68.6% upcycled ingredients!

- Tooth Powder 100% natural, 20% upcycled.

- Massage Oil

There is a greater consumer demand for natural and organic ingredients in the Beauty and Personal Care Market, this is cause for even greater ecological efficiency. Reclaiming waste helps us to put a higher value on our way of life, without costing us the planet!

Learn more about the ways you can incorporate sustainability into your product development, here.

Leave A Comment

You must be logged in to post a comment.